-

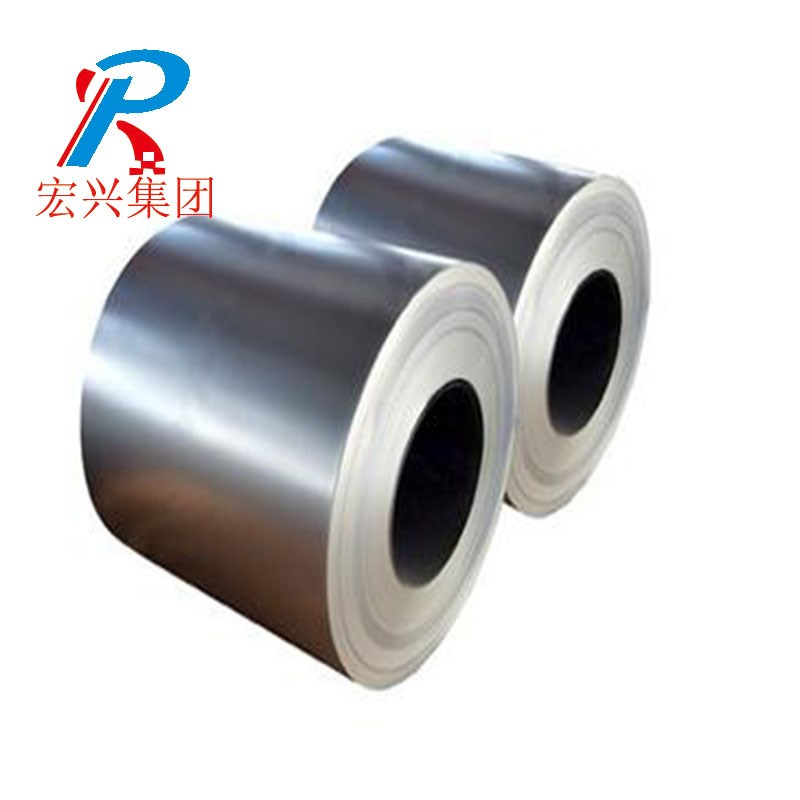

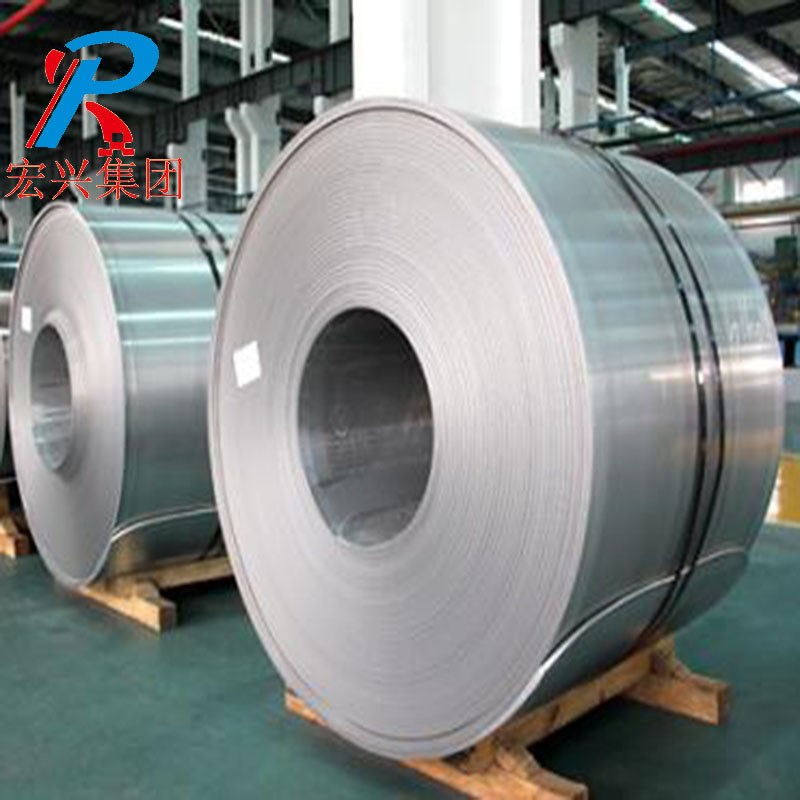

Aluminized Zinc Coils

The surface of the aluminized and galvanized steel coil is characterized by smooth, flat and gorgeous stars, and its base color is silver-white. The special coating structure makes it have excellent corrosion resistance. The normal service life of aluminized galvanized sheet is up to 25a, and its heat resistance is good. Aluminized Zinc Coils can be used in high temperature environment at 315 C. The adhesion between coating and paint film is good, and it has good processing performance. It can be punched, sheared and welded. The surface conductivity is very good.

-

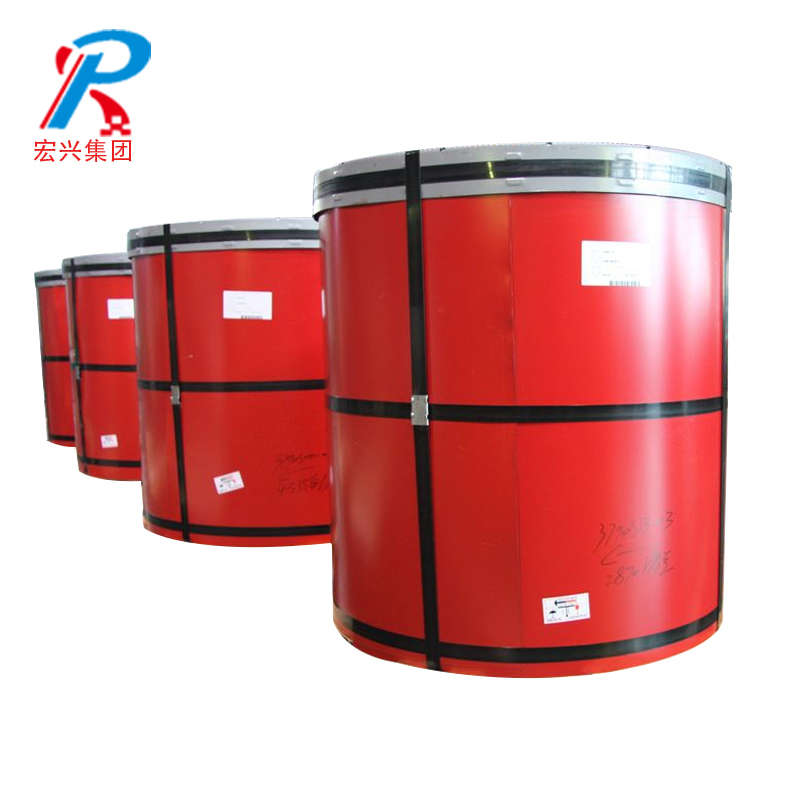

Pre-painted Galvanized Steel Coils

Pre-painting Galvanized Iron Panel is used special steel coil as raw material and surfaces (covered with) is painted a layer of organic polymer (or polymer print film),which has advantages ofmetal material and the organic polymer. Not only good adhesive of Organic polymer,formability,corrosion resistance,decorative,but also high strength and easy processing,can be easily punching,bending,deep drawing,welding,etc. So it has perfact practicality,decorative,workability,durability.Currently,the PCM is produced by print film roller coating process and roller painting.

-

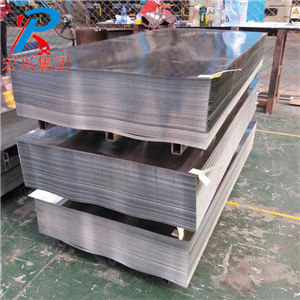

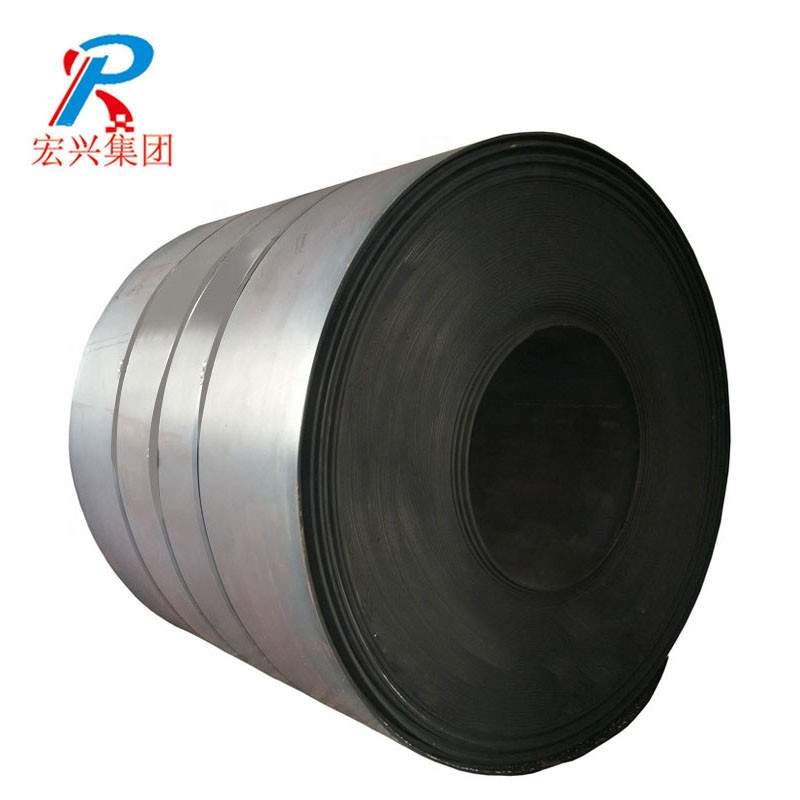

Cold Rolled Steel Coils

Cold rolled steel coil is the steel produced by cold rolling. Cold rolling is the process of further rolling steel sheet to target thickness at room temperature. Compared with hot-rolled steel sheet, cold-rolled steel sheet is more precise in thickness, smooth and beautiful in surface, and has various superior mechanical properties, especially in processing performance. Because the cold-rolled coil is brittle and hard, it is not suitable for processing, so the cold-rolled steel plate usually requires annealing, pickling and surface leveling before being delivered to customers. The maximum thickness of cold rolling is less than 0.1-8.0MM, for example, the thickness of cold rolled steel plate in most factories is less than 4.5MM, and the minimum thickness and width are determined according to the equipment capacity and market demand of each factory.

-

Hot Rolled Steel Coils

Hot rolled, or hot rolled coil, is made of slab (mainly continuous casting slab) as raw material, which is heated by roughing mill and finishing mill.The hot strip from the last finishing mill is cooled by laminar flow to set temperature, coiled into strip coil by coiler. The cooled strip coil is processed into steel plate by different finishing lines (leveling, straightening, cross cutting or longitudinal cutting, inspection, weighing, packaging and marking, etc.) according to different needs of users. Flat coil and longitudinal cut strip products.

-

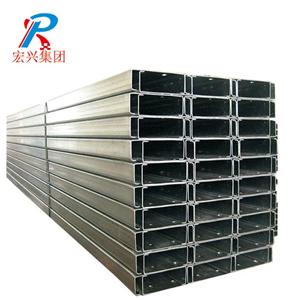

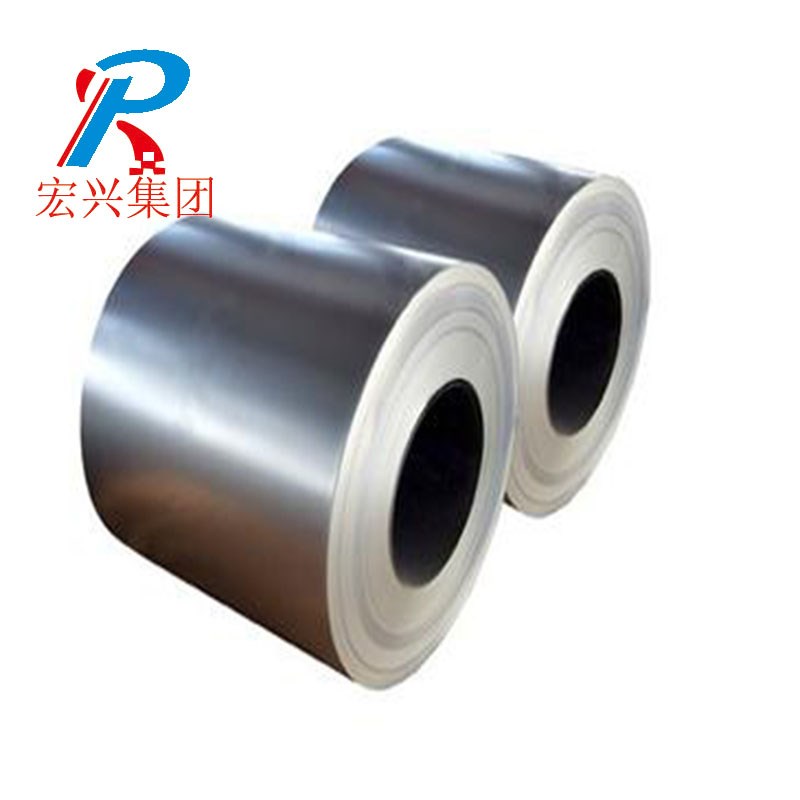

Galvanized Steel Coils

Galvanized coil, the thin steel plate immersed in the molten zinc bath, so that its surface adheres to a layer of zinc thin steel plate. At present, continuous galvanizing process is mainly used to produce galvanized steel sheet, which is made by continuously immersing coiled steel sheet in galvanized bath and alloying galvanized steel sheet. This kind of steel plate is also made by hot dipping method, but it is heated to about 500 C immediately after the trough is out to form zinc and iron alloy film. The galvanized coil has good adhesion and weldability of the coating.

Steel Coils

Get the latest price? We'll respond as soon as possible(within 12 hours)