-

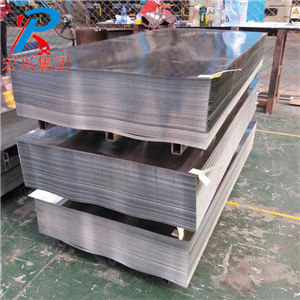

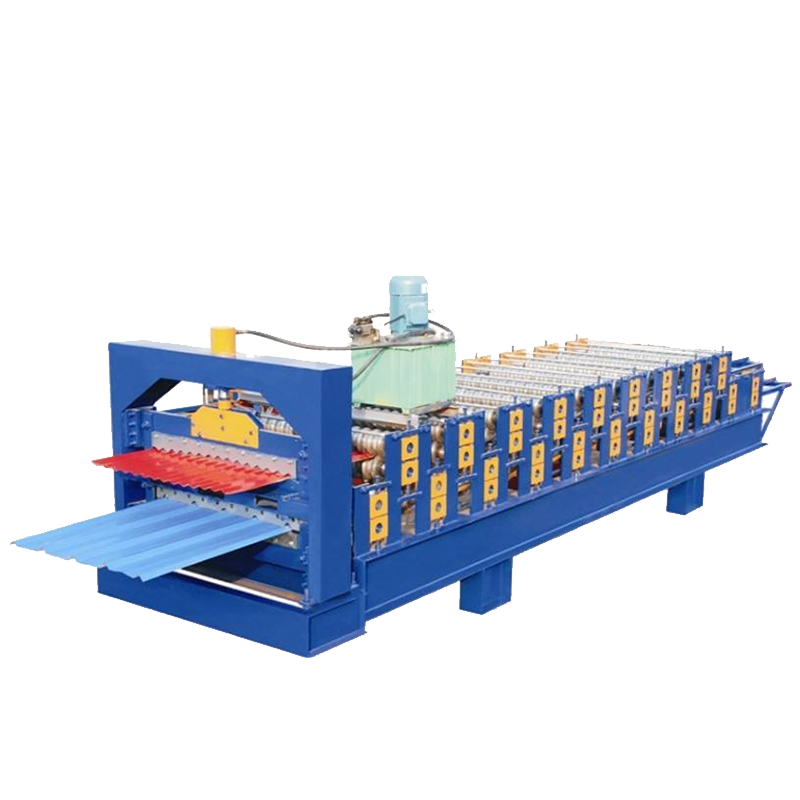

tile roll forming machine

Two levels wave and trapezoid tile roll forming machine with cutting systerm is operated by a computer. It is easy to operate and can be set up in many languages to meet the needs of customers in many countries and regions. Two levels wave and trapezoid tile roll forming machine with cutting systerm is made up of laying out, forming and post-forming cutting. Its color plate has smooth and beautiful appearance, uniform paint pattern, high strength and durability. It is widely used in industrial and civil buildings, such as factory buildings, warehouses, gymnasiums, exhibition halls, cinemas and other rooms and walls. Two levels wave and trapezoid tile roll forming machine with cutting systerm using high quality steel products, complete product types and models.The technical performance index has reached the advanced level at home and abroad. Two levels wave and trapezoid tile roll forming machine with cutting systerm Special design and facture can be carried out according to user's requirements, and at the same time adapt to market changes, constantly upgrade and update.

-

welding machine

The welding machine with over-voltage, under-voltage, over-current, overload automatic protection functions. Portable welding machine high efficiency, low no-load loss and more energy saving. With automatic compensation function for power grid voltage fluctuations. Easy arc starting. Small spatter, low noise, stable welding current and good forming.

-

ERW Steel Pipes

ERW Steel Pipes is a kind of steel pipe which is formed by bending steel strip or steel plate into circular or square shape and then welded on the surface with joints. The blank used in welded steel pipe is steel plate or strip steel. Advantages and features Generally, ERW steel pipe has high accuracy, uniform wall thickness, high brightness of inner and outer surface of pipe (the brightness of steel pipe determined by the surface grade of steel plate), and can be arbitrarily ruled. Therefore, it embodies its economy and beauty in the application of high precision, medium and low pressure fluids. Welded steel pipe has the advantages of simple production process, high production efficiency, low cost and rapid development.

-

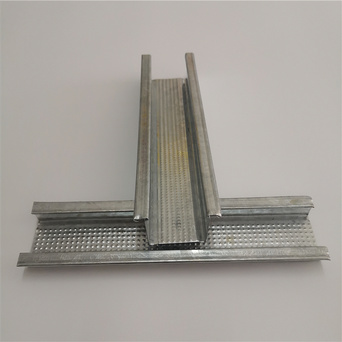

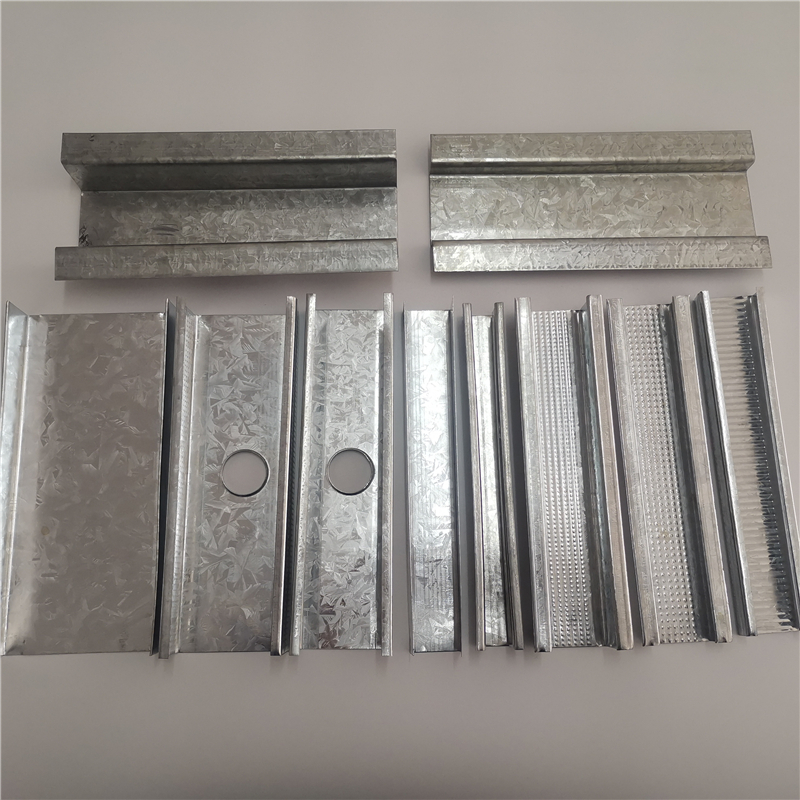

Galvanized Drywall Runner

Keel is a kind of building material used to support modelling and fixing structure. It is widely used in hotels and terminal buildings. Passenger station, station, theatre, shopping mall, factory, office building, old building renovation, indoor decoration, roof and other places. Keel is the skeleton and base material of decoration, which is widely used. There are many kinds of keel, which can be divided into wood keel, light steel keel, aluminium alloy keel, steel keel and so on.

-

Galvanized Wall Angle

Ceiling Channel is a new building material. With the development of modernization in China, Ceiling Channel is widely used in hotels, terminal buildings, train stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings, interior decoration, roof and other places. Ceiling Channel suspension roof has the advantages of light weight, high strength, water-proof, shock-proof, dust-proof, sound insulation, sound absorption, constant temperature and so on. At the same time, it has the advantages of short construction period and simple construction.

-

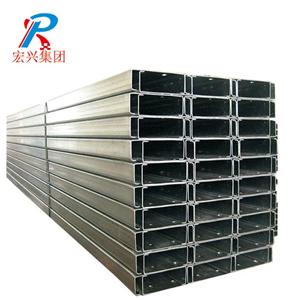

Galvanized Ceiling Channel

Ceiling Channel is a new building material. With the development of modernization in China, Ceiling Channel is widely used in hotels, terminal buildings, train stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings, interior decoration, roof and other places. Ceiling Channel suspension roof has the advantages of light weight, high strength, water-proof, shock-proof, dust-proof, sound insulation, sound absorption, constant temperature and so on. At the same time, it has the advantages of short construction period and simple construction.

-

pile wire cage welding machine

Our company's reinforcing cage rolling welding machine equipment can automatically form reinforcing cage of 2 m-27 m in length at one time, and equipped with intelligent welding manipulator with independent intellectual property rights. Compared with manual binding cage, it has high production efficiency, material saving, strong cage and standard shape. It is widely used in the construction of cast-in-place piles in large bridges, high-speed railways, highway construction and other fields.

-

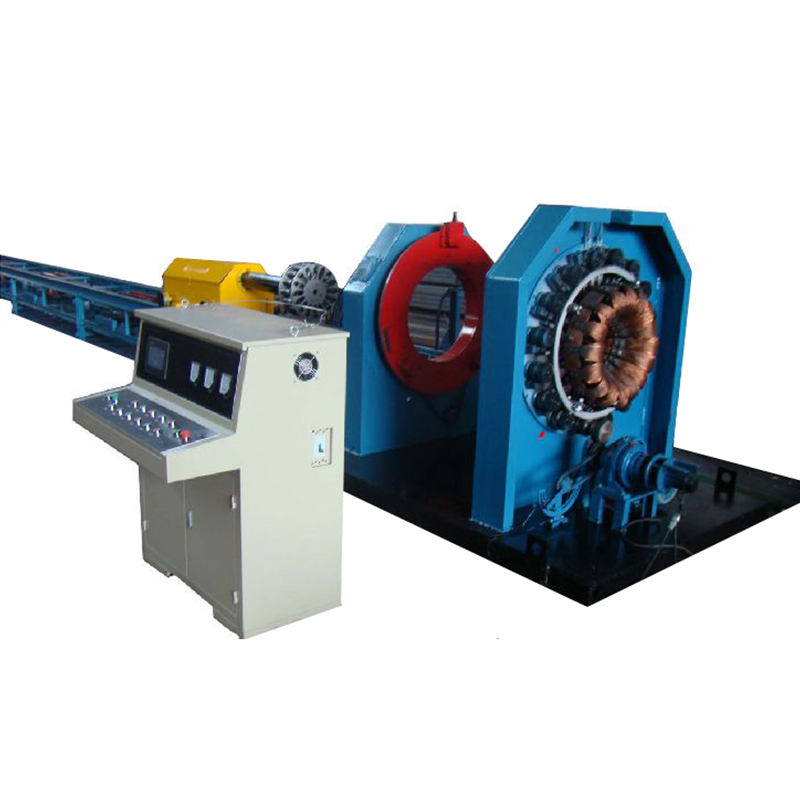

Roll welding machine

Roll welding machine is widely used in cast-in-place pile construction in large bridges, high-speed railway construction and other fields. Wire Cage welding machine is one of the most necessary equipment to produce reinforced concrete pipes. There is pushing style, another is the Pulling. Our company pipe cage welding machine is fully automatic operation, the whole production process only needs one person operation. It makes up of four systems: The Main rotary plate; Pushing wire Plate; Diameter changing structure; and Cooper welder, they are working, driven by the separate motor. The Variable Frequency speed control system regulated to make the spiral pitch, the angle of ball joint.

-

vertical concrete pipe making machine

Vertical radial extrusion pipe manufacturing technology as a new type of pipe manufacturing technology has the greatest advantage of using dry and hard concrete, vertical production can be immediately demoulded.Instantaneous extrusion molding, each tubeonly 2 to 4 minutes, high production efficiency. The radial extrusion pipe-making machine issuitable for producing small and medium-sized concrete drainage pipes. Its diameter range is300mm-1200mm. Its standard length is 2-3m. It can also produce reinforced concrete cement pipes with flexible joints and pipe jacking without reinforced concrete cement pipes.

-

Gymnasium activities retractable grandstand chairs

The seat is made of high-density polyethylene (HDPE) using a hollow blow molding process. The overall design of the seat is ergonomic to achieve a comfortable sitting feeling and reducesitting fatigue. The seat has superior mechanical performance, high strength, impact resistance, safety, good weather resistance, acid and alkali resistance, and antistatic. The seat design, shape and installation method meet the international general requirements,which are beautiful in appearance, comfortable to sit on, and easy to install, maintain and manage. Fixed grandstand seats can be divided into flat-mounted, side-mounted, and vertical-mounted seats with different installation methods, as well as integrated chairs and flap chairs, depending on the different needs of the venue.

-

Prestressed Concrete PHC Pile Moulds

Product Name: Prestressed Concrete PHC Pile Moulds Concrete pile mould is position fixing is made by radial tongue-and groove and axial taper pin. Manufactured stage by stage and binded by bolts at last, the mould is characteristic with the advantages of esay transportation, quick assembling,correct position fixing, good rigidity and smooth working. We are professional manufacturer of Pre-stressed Concrete Pile Production Line. We have engaged in this area for many years and own mature technology, full experience. Our products are in accordance with the standard GB-13476-1999, the quality is guaranteed. Certification: ISO9001:2008 Running Wheel: 600-1800mm lengh: 7-60m Product: Concrete spun pile steel mould Shaping Mode: Die Casting

-

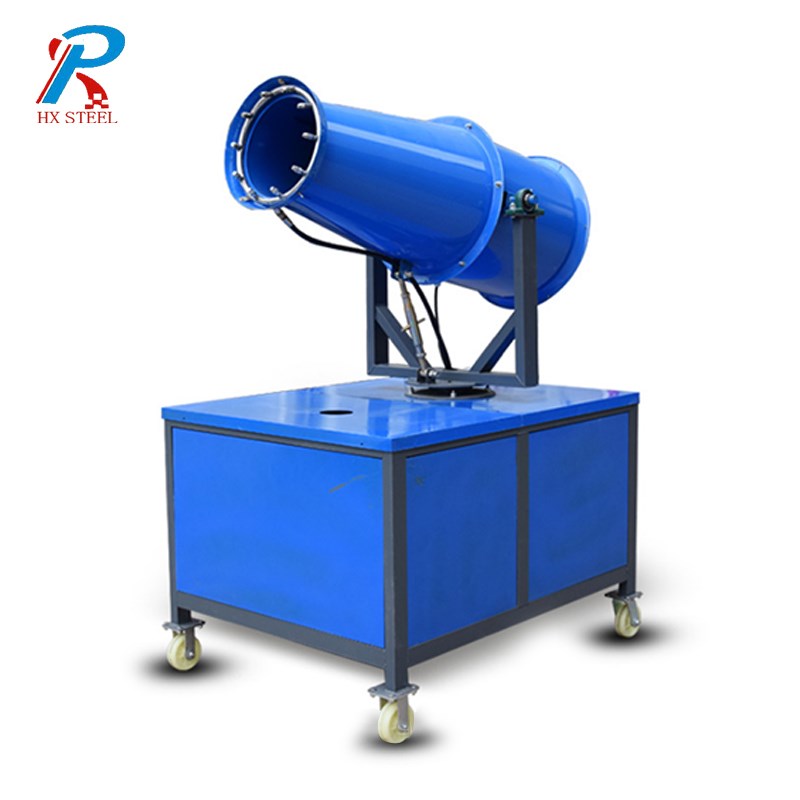

Dust removal spray machine

Scope of application: Humidification, cooling, and dust reduction on construction sites; Environmental protection industry, mines, coal yards, terminals, steel mills and other dusty construction sites for dust removal and cooling and humidification; Forest protection, urban landscaping, spraying of trees and trees to prevent pests and diseases; City streets, station terminals, school airports, public places, garbage sites, sanitation and epidemic prevention, etc., disinfection, dust removal and cooling.

- Home >

- Products

Products

Get the latest price? We'll respond as soon as possible(within 12 hours)