-

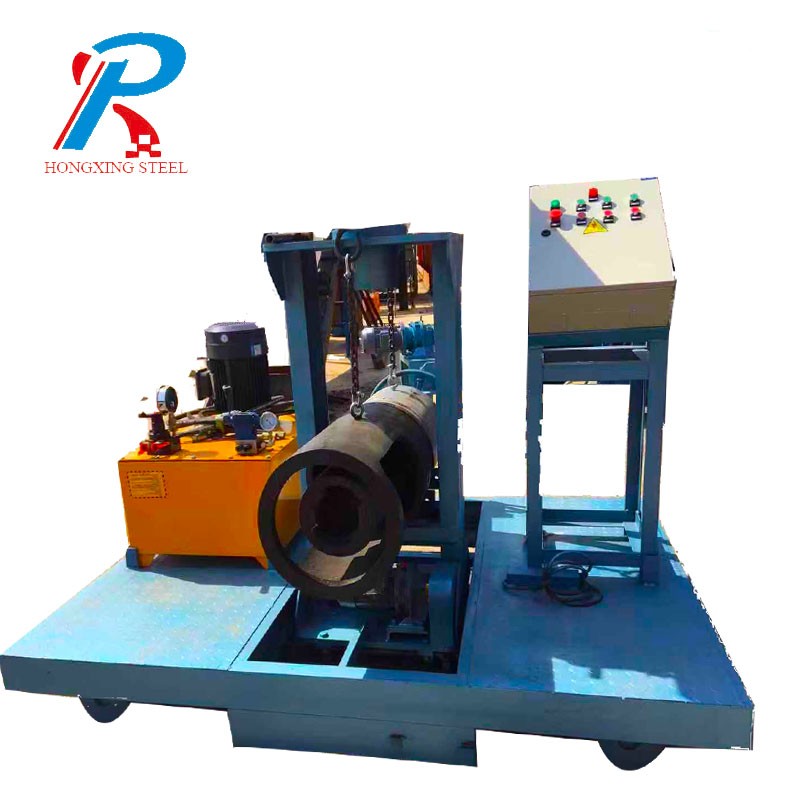

Round Pipes Making Machine

Vertical radial extrusion pipe manufacturing technology as a new type of pipe manufacturing technology has the greatest advantage of using dry and hard concrete, vertical production can be immediately demoulded.Instantaneous extrusion molding, each tubeonly 2 to 4 minutes, high production efficiency. The radial extrusion pipe-making machine issuitable for producing small and medium-sized concrete drainage pipes. Its diameter range is300mm-1200mm. Its standard length is 2-3m. It can also produce reinforced concrete cement pipes with flexible joints and pipe jacking without reinforced concrete cement pipes.

-

Vertical Radial Extruder

Vertical radial extrusion pipe manufacturing technology as a new type of pipe manufacturing technology has the greatest advantage of using dry and hard concrete, vertical production can be immediately demoulded.Instantaneous extrusion molding, each tubeonly 2 to 4 minutes, high production efficiency. The radial extrusion pipe-making machine issuitable for producing small and medium-sized concrete drainage pipes. Its diameter range is300mm-1200mm. Its standard length is 2-3m. It can also produce reinforced concrete cement pipes with flexible joints and pipe jacking without reinforced concrete cement pipes.

-

Forklift truck and bulldoer

Forklift is an industrial transport vehicle, which refers to a variety of wheeled transport vehicles for loading and unloading, stacking and short-distance transportation of palletized goods. The international organization for standardization, known as industrial vehicles, is often used to transport large storage items, usually powered by fuel engines or batteries.

-

Scraper Forklift of Electric

Forklift is an industrial transport vehicle, which refers to a variety of wheeled transport vehicles for loading and unloading, stacking and short-distance transportation of palletized goods. The international organization for standardization, known as industrial vehicles, is often used to transport large storage items, usually powered by fuel engines or batteries.

-

PDL Series automatic batching machine

PLD series concrete batchingmachine is a kind of automatic batchingequipment which is used in combination with the mixer. lt can automaticallycomplete the batching process of sand, stone, cement and other materialsaccording to the concrete proportion set by the user. This machine has the characteristics of accurate weighing, high precisionof batching, high speed and accurate control function, etc. It is flexible incombination with the corresponding mixer, and convenient in movementand inslat It is an ideal equipment for producing high quality concrete.

-

Batching concrete pile feeder

PLD series concrete batchingmachine is a kind of automatic batching equipment which is used in combination with the mixer. lt can automatically complete the batching process of sand, stone, cement and other materials according to the concrete proportion set by the user. This machine has the characteristics of accurate weighing, high precisionof batching, high speed and accurate control function, etc. It is flexible incombination with the corresponding mixer, and convenient in movementand inslat It is an ideal equipment for producing high quality concrete.

-

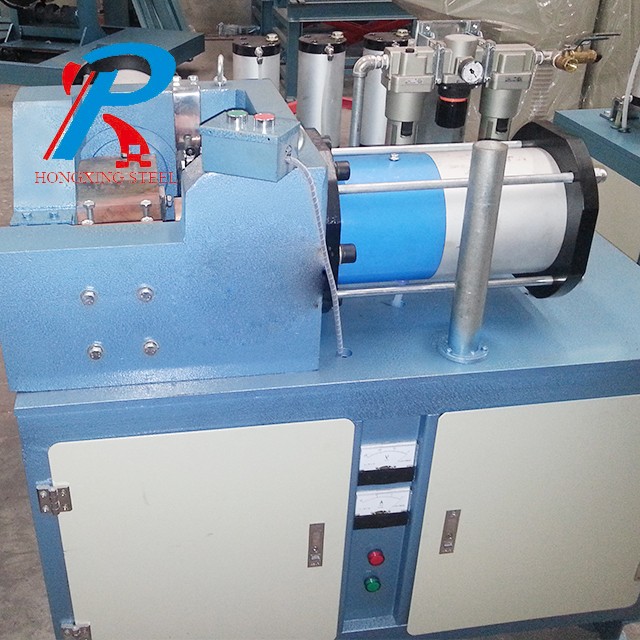

Prestressed concrete tension machine

Tension machine is a kind of feedthrough pre-tensioing jack with a tension rod in the center, having 4 types of tensioning strength, namely: 1000 KN, 2000 KN, 3000 KN, 4000 KN. As the end of the tension rod is connected to the anchor with thread, it can be applied to various forged anchors, chilled iron anchor used for stayed-cable bridge and other similar anchors, as well as pre-tension pulling for pipes. In accordance with actual requirement, the support of two heavy-weight jacks can be replaced with a baseplate and rolling hinged bearing provided by the manufacturer, to be used as a vertical jack, or for horizontal pushing during installation. The customer can also demand a change in thread specifications for the connection of the anchor to enlarge the scope of application.

-

Prestressed concrete Tension jack tension machine

Tension machine is a kind of feedthrough pre-tensioing jack with a tension rod in the center, having 4 types of tensioning strength, namely: 1000 KN, 2000 KN, 3000 KN, 4000 KN. As the end of the tension rod is connected to the anchor with thread, it can be applied to various forged anchors, chilled iron anchor used for stayed-cable bridge and other similar anchors, as well as pre-tension pulling for pipes. In accordance with actual requirement, the support of two heavy-weight jacks can be replaced with a baseplate and rolling hinged bearing provided by the manufacturer, to be used as a vertical jack, or for horizontal pushing during installation. The customer can also demand a change in thread specifications for the connection of the anchor to enlarge the scope of application.

-

Auto heading cutting and moving machine

The auto machine matched with cutter and heading machine together,achieve to auto cutting,heading and moving bar away way .NC controller,mote adopts VFD,accurate speed,stably work,handle and Automatic way change any time,it can work in any where,easy installation,energy-efficient,after sale service with commercial cost. The machine is easy to operate, with high-quality processing and high speed, free from the impact of the environment, which could upset 16-40mm HRB335 and HRB400 grade steel rebar.

-

Tension machine for Electric Concrete poles

Prestressed tension is to pre-tension in the members, so that the pre-tensioned members are subjected to tensile stress, and then make them produce a certain deformation, to cope with the load of the steel structure itself, including the load of the roof weight, wind load, snow load, earthquake load and so on. Generally, steel strands, jacks, anchor plates, splints are used for tensioning.

-

Steel wire heading and cutter machine

Quick Details Applicable Industries:Building Material Shops, Construction works , Energy & Mining After-sales Service Provided:Online support, Field installation, commissioning and training Warranty:1 Year Product name:heading machine Capacity:15KVA Color:Customer's Requirement Weight:1200kg Length:10.4m-34.4m

-

Automatic heading and cutter machine

The auto bar moving machine matched with cutter and heading machine together,achieve to auto cutting,heading and moving bar away way .NC controller,mote adopts VFD,accurate speed,stably work,handle and Automatic way change any time,it can work in any where,easy installation,energy-efficient,after sale service with commercial cost. The machine is easy to operate, with high-quality processing and high speed, free from the impact of the environment, which could upset 16-40mm HRB335 and HRB400 grade steel rebar.

- Home >

- Products

Products

Get the latest price? We'll respond as soon as possible(within 12 hours)